Exploring the Boundless Potential of Laser Technology

The Revolutionary Impact of Laser Technology

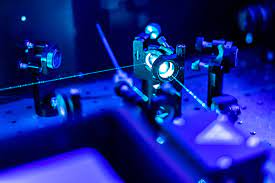

From surgical procedures to cutting-edge industrial applications, laser technology has revolutionized various fields with its precision and versatility. Originally conceptualized in the mid-20th century, lasers have evolved into indispensable tools that continue to push boundaries and open new possibilities.

Medical Advancements

In the medical field, lasers have transformed treatments by offering minimally invasive procedures with reduced recovery times. Laser technology is widely used in dermatology for skin resurfacing, tattoo removal, and hair removal. In ophthalmology, LASIK surgery corrects vision impairments with remarkable accuracy.

Industrial Applications

In manufacturing and industry, lasers are utilized for cutting, welding, marking, and engraving materials such as metal, plastic, and wood. The precision of laser beams allows for intricate designs and high-quality finishes that traditional tools cannot achieve. Additionally, lasers are crucial in measuring devices like rangefinders and barcode scanners.

Scientific Research

Laser technology plays a vital role in scientific research across various disciplines. In physics, lasers are used to study light-matter interactions and quantum phenomena. In chemistry, lasers enable spectroscopy techniques for analyzing molecular structures. Furthermore, lasers are integral to advancements in telecommunications and data storage.

Future Prospects

As laser technology continues to advance rapidly, its applications are expected to expand further. Innovations such as ultrafast lasers for precise material processing and medical diagnostics show great promise. Additionally, emerging fields like quantum computing rely on laser technology for manipulating quantum states.

In conclusion, laser technology has profoundly impacted diverse sectors with its precision and adaptability. As research and development efforts drive innovation forward, the future of laser technology holds boundless potential for shaping our world in ways we have yet to imagine.

8 Advantages of Laser Technology: Precision, Versatility, and Beyond

- Precision

- Versatility

- Minimally Invasive

- Efficiency

- Non-contact

- High Quality Results

- Speed

- Innovative Applications

7 Drawbacks of Laser Technology: Cost, Safety, and Limitations

- High initial cost of laser equipment can be prohibitive for small businesses and individuals.

- Improper handling of lasers can pose serious safety hazards, including eye damage and skin burns.

- Maintenance and repair of laser systems can be complex and costly, requiring specialized expertise.

- Laser technology may not be suitable for all materials or applications, limiting its versatility in certain industries.

- Some laser processes generate hazardous fumes or byproducts that require proper ventilation and disposal measures.

- Power consumption of high-powered lasers can be significant, leading to increased energy costs over time.

- Regulatory compliance and certification requirements for using lasers in certain fields can add bureaucratic hurdles.

Precision

Laser technology stands out for its unparalleled precision, making it a game-changer in numerous applications. Whether in medical procedures, industrial manufacturing, or scientific research, the focused beam of a laser enables pinpoint accuracy that traditional tools cannot match. This precision not only enhances the quality of outcomes but also minimizes errors and waste, ultimately leading to more efficient and effective processes. The ability of laser technology to deliver precise results consistently has paved the way for advancements in fields where accuracy is paramount, showcasing its indispensable role in shaping modern innovation and progress.

Versatility

The versatility of laser technology is truly remarkable, as it finds applications in a diverse array of fields, spanning from medicine to manufacturing. In the medical realm, lasers are instrumental in performing precise surgeries, treating skin conditions, and even correcting vision impairments. Meanwhile, in manufacturing processes, lasers are indispensable for cutting, welding, and engraving various materials with unparalleled precision. This adaptability across such different sectors showcases the immense potential of laser technology to revolutionize multiple industries and contribute to advancements in science and technology.

Minimally Invasive

Laser technology’s minimally invasive nature is a significant advantage, as it frequently leads to reduced scarring and quicker recovery periods. By utilizing focused laser beams to target specific areas with precision, procedures such as skin treatments and surgeries can be performed with minimal damage to surrounding tissues. This not only enhances the cosmetic outcomes for patients but also promotes faster healing and shorter post-operative downtime, ultimately improving the overall patient experience and quality of care.

Efficiency

Laser technology offers unparalleled efficiency by enabling rapid and precise processing of materials. The focused laser beams can swiftly cut, weld, or engrave with exceptional accuracy, reducing production times and minimizing errors. This efficiency not only enhances productivity in manufacturing and industrial settings but also ensures consistent quality in the final products. The ability of laser technology to swiftly and accurately process materials showcases its immense value in streamlining operations and delivering superior results across various industries.

Non-contact

One significant advantage of laser technology is its non-contact nature, particularly evident in processes like laser cutting and engraving. Unlike traditional methods that involve physical contact with the material, laser technology allows for precision cutting and engraving without touching the surface. This non-contact feature not only ensures a cleaner and more accurate outcome but also minimizes the risk of damage to delicate materials. Additionally, the absence of physical contact reduces wear and tear on equipment, leading to increased efficiency and longevity in industrial applications.

High Quality Results

One of the key advantages of laser technology is its ability to deliver high-quality results. By producing clean cuts and precise markings, lasers ensure impeccable outcomes in various applications. Whether it’s intricate designs on materials or precise surgical incisions, the precision of laser beams guarantees a level of quality that traditional methods often struggle to achieve. This reliability in producing fine details and accurate results makes laser technology a preferred choice in industries where excellence and precision are paramount.

Speed

Laser technology’s remarkable speed is a game-changer in industrial settings, where efficiency and productivity are paramount. With the ability to achieve rapid processing speeds, lasers streamline manufacturing processes, such as cutting, welding, and engraving, leading to significant time savings and enhanced output. This accelerated pace not only boosts productivity but also allows for the quick completion of intricate tasks with precision, making laser technology an invaluable asset in optimizing operations and meeting demanding production schedules.

Innovative Applications

Constant advancements in laser technology pave the way for a myriad of innovative applications that continue to push the boundaries of what is possible. From enhancing medical procedures to revolutionizing industrial processes, the versatility and precision of lasers open up new and exciting opportunities for various industries. These advancements not only improve existing technologies but also inspire creative solutions to challenges, driving progress and innovation across multiple fields.

High initial cost of laser equipment can be prohibitive for small businesses and individuals.

The high initial cost of laser equipment poses a significant challenge for small businesses and individuals looking to leverage laser technology. The investment required to purchase and maintain laser machines can be prohibitive, limiting access to these advanced tools for those with limited financial resources. This barrier to entry may hinder small businesses from adopting laser technology for tasks such as engraving, cutting, or marking, ultimately impacting their competitiveness in the market. Additionally, individuals seeking to explore personal projects or entrepreneurial ventures may find themselves unable to afford the upfront expenses associated with acquiring laser equipment, thereby restricting their ability to fully tap into the potential benefits of this innovative technology.

Improper handling of lasers can pose serious safety hazards, including eye damage and skin burns.

Improper handling of lasers can pose serious safety hazards, including eye damage and skin burns. The high intensity of laser beams can cause irreversible harm if not used with caution and proper safety measures. Direct exposure to laser radiation can result in retinal damage or even permanent blindness, highlighting the critical importance of adhering to safety protocols when working with laser technology. Additionally, skin burns can occur if the skin is exposed to concentrated laser beams, emphasizing the need for proper training and supervision to mitigate risks associated with the misuse of lasers.

Maintenance and repair of laser systems can be complex and costly, requiring specialized expertise.

Maintenance and repair of laser systems can present a significant challenge due to their complexity and the need for specialized expertise. Ensuring the proper functioning of laser equipment often involves intricate procedures that demand skilled technicians with in-depth knowledge of laser technology. Additionally, sourcing replacement parts and conducting repairs can be costly, potentially leading to downtime and increased operational expenses for organizations relying on laser systems. The intricacies involved in maintaining and repairing laser technology underscore the importance of investing in qualified professionals and robust maintenance protocols to mitigate risks and ensure optimal performance.

Laser technology may not be suitable for all materials or applications, limiting its versatility in certain industries.

One significant drawback of laser technology is its limited suitability for all materials or applications, which can restrict its versatility in certain industries. While lasers excel in precision cutting and marking of materials like metal and plastic, they may not be as effective when working with highly reflective surfaces or transparent materials. This limitation can pose challenges in industries where a wide range of materials need to be processed or treated, potentially requiring alternative methods to achieve desired results. The specificity of laser technology may hinder its widespread adoption in industries that demand versatility across various material types and applications.

Some laser processes generate hazardous fumes or byproducts that require proper ventilation and disposal measures.

Some laser processes generate hazardous fumes or byproducts that pose a significant environmental and health concern. The need for proper ventilation systems and disposal measures to handle these emissions adds complexity and cost to utilizing laser technology in various industries. Failure to address this con effectively can result in air pollution, workplace safety hazards, and regulatory compliance issues. It is crucial for organizations using laser technology to prioritize the implementation of appropriate safety protocols and environmental practices to mitigate the risks associated with harmful fumes and byproducts.

Power consumption of high-powered lasers can be significant, leading to increased energy costs over time.

The power consumption of high-powered lasers poses a notable con, as it can result in substantial energy usage and elevated operational costs. High-powered lasers require significant amounts of electricity to function efficiently, leading to increased energy consumption over time. This heightened power demand not only contributes to higher utility bills but also raises concerns about the environmental impact associated with the generation of this additional energy. Addressing the power consumption challenge of high-powered lasers is crucial for promoting sustainability and mitigating the long-term financial implications of their energy-intensive operation.

Regulatory compliance and certification requirements for using lasers in certain fields can add bureaucratic hurdles.

Regulatory compliance and certification requirements for utilizing lasers in specific fields can present significant challenges and bureaucratic hurdles. Industries such as healthcare, manufacturing, and research must adhere to strict guidelines to ensure the safe and proper use of laser technology. Obtaining the necessary certifications and meeting compliance standards can be time-consuming and costly, potentially delaying projects and hindering innovation. Moreover, navigating the complex regulatory landscape surrounding lasers may require specialized expertise, adding an additional layer of complexity for organizations seeking to leverage this technology effectively.